Brochures

Our approach is distinctly innovative. We constantly seek new ways to increase client

Our approach is distinctly innovative. We constantly seek new ways to increase client

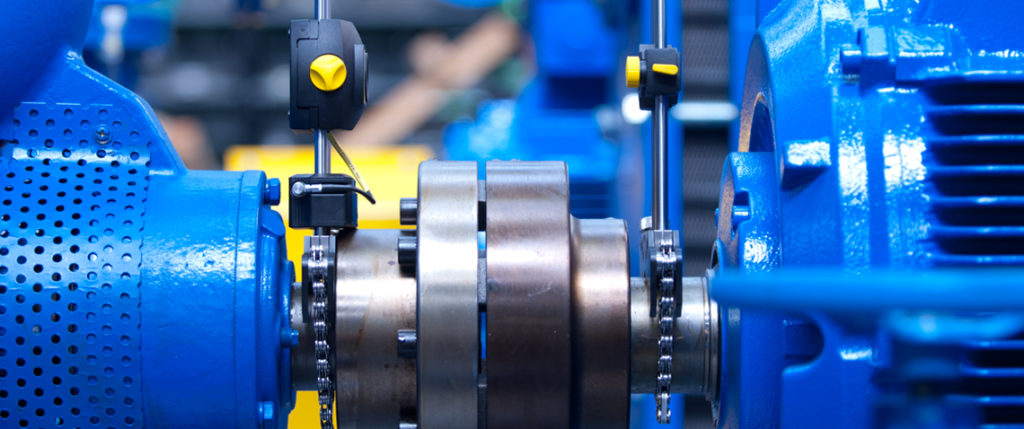

Precise Reliability provides a complete Laser Shaft Alignment solution to all industries, using Fixturlaser alignment equipment.

Some of the industries served with our Shaft Alignment, Flatness Alignment and Bore Alignment services are: –

We only use Fixturlaser equipment as we consider it the best in the world for accuracy, ease of use and reliability.

The Fixturlaser is designed for speed and ease of use in a busy industrial environment. With its user-friendly interface and extensive capabilities, the Fixturlaser system works it’s alignment magic in record time and is the ideal choice for maintenance engineers.

The state of the art CCD digital laser technology prevents interference from bright sunlight that can often be a problem with equipment from other manufacturers.

The Fixturlaser laser system boasts a color LCD touch screen display with clear icons and the benefit of animated graphics to guide the user through an easy alignment process step by step.

This shaft alignment system unusually also uses dual line lasers (instead of a dot-laser) and uses large detectors in its receivers. I.e. it can pick up the laser beam over a much greater target area. This is a huge benefit when setting up the laser as it removes most of the need for rough alignment steps. Just set everything up by eye and usually the beam is somewhere on the target. Minor adjustments thereafter and you are good to go. Very quick and easy.

The Fixturlaser comes with cleverly designed Pre-assembled fixtures that allow the laser units to be attached in seconds. We can also design and manufacture special brackerty to allow you to aligh shafts in difficult situations. just let us know your requirements.

The latest wireless connectivity allows the user complete freedom of movement which again is a great benefit when using the system in difficult conditions.

This Fixturlaser system comes with an Express Alignment mode which automatically samples alignment data once the equipment is set-up and running. This can allow data capture in a very short time. From the time you open the case to the first data being received can be as little as five or six minutes.